First we start with the main line add caps if needed line bore and finish with a line hone.

This is a pic of a 010/020 block with 2482 center caps being line honed.

Next we blue print bore the cam tunnel for over size bearings or roller bearings as this fixture locates center to center distance of the main line and cam center line and keeps the cam tunnel in line with the main line.

This is a pic of a Dart Aluminum block with a .391 raised cam tunnel that we bored out for 55MM cam shaft.

From ther we install it in our CNC machine and index it in the machine. And before we do any machine work we probe the block for deck heights, Cylinder locations in X and Y and cylinder size as it tells us how far its of to blue print.

This is a pick of a Dart Little-M block being probed out.

From there we machine the decks 45 degrees from the crank and cam center lines.

SORRY NO PIC AVAILABLE AS I WILL UP DATE TOMORROW

Next we blue print bore the cylinders or on some of the older 010 blocks that are out of blue print we can bore to the preprobed location

Dart block being bore to blue print.

Once bore we can chamfer the tops of the cylinders yo a desired depth

NO PIC AVAILABLE YET.

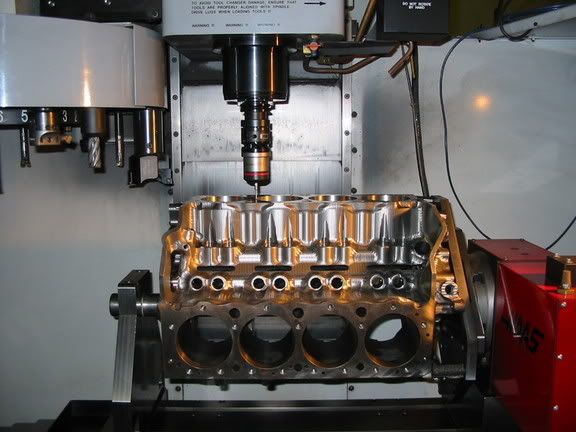

Next we blue print bore the lifter bores to .875 or .904 or bush back to standard.

Dart Little-M block being machined for .875 lifter bores.

From there we install the block in our Sunnen Hone intall the torque plate and hone the cylinders to the desired size.

Dart Little-M block being honed

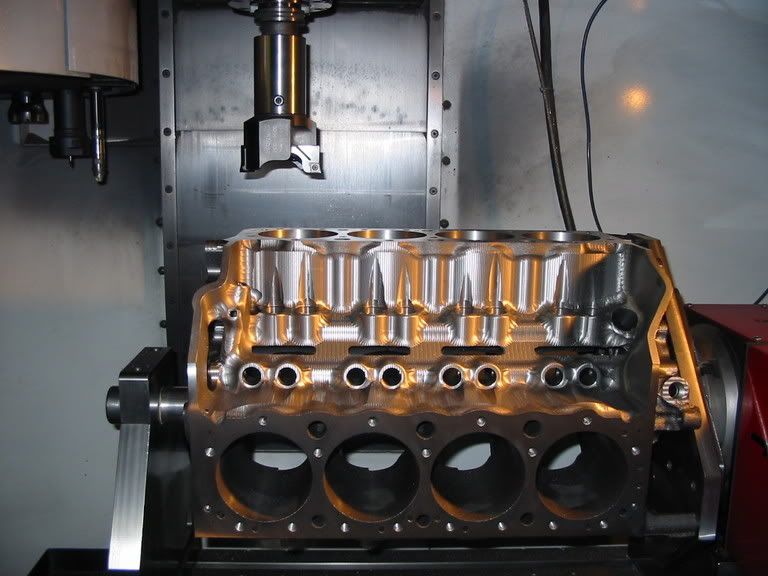

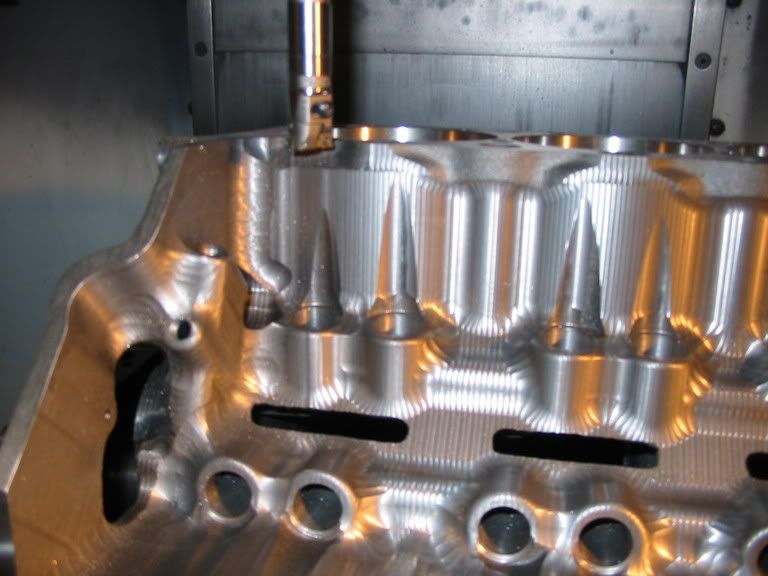

Finished products.

Dart Little-M block

This is a pic of a blower engine our engine shop builds for a pulling team.

Comments are welcome and I will have other pics for this post tomorrow.