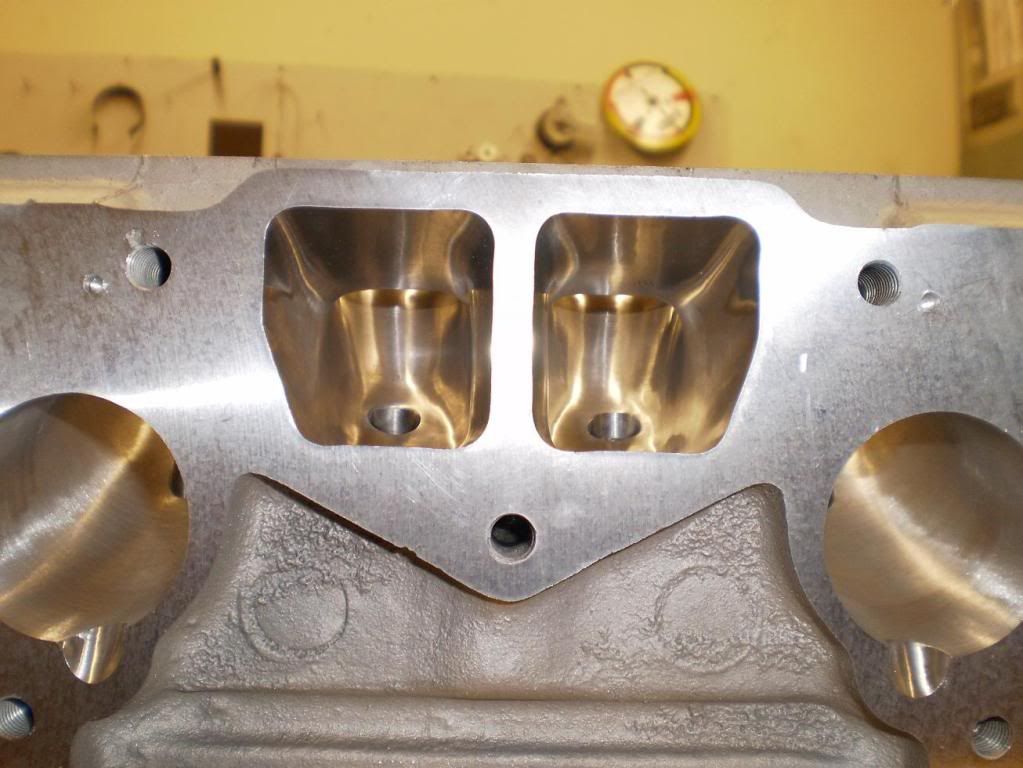

So, this is the combustion chamber of my current cylinder head, and I am thinking that it can be better. it's 55cc volume, bores are 88mm and the piston is dished with a quench band around the outer 4mm of the piston, over the ring pack.

The valves have been unshrouded and the chamber walls are undercut slightly, not much has been taken from the side opposite the spark plug as I would prefer the airflow NOT enter the chamber that side...I want it to flow across the valve and enter on the spark plug side/exhaust valve side as much as possible.

I am considering welding the spark plug boss solid and re-drilling it at an angle, bringing the plug in pointed at the exhaust valve. This would let me open the pocket up in front of the intake valve, and move the electrode out of the way of the incoming intake charge. I have a photo of a head that was done this way; and have done the welding on a spare, cracked head...Setting it up to machine the spark plug locations isn't exactly easy without having a milling machine readily available right now.

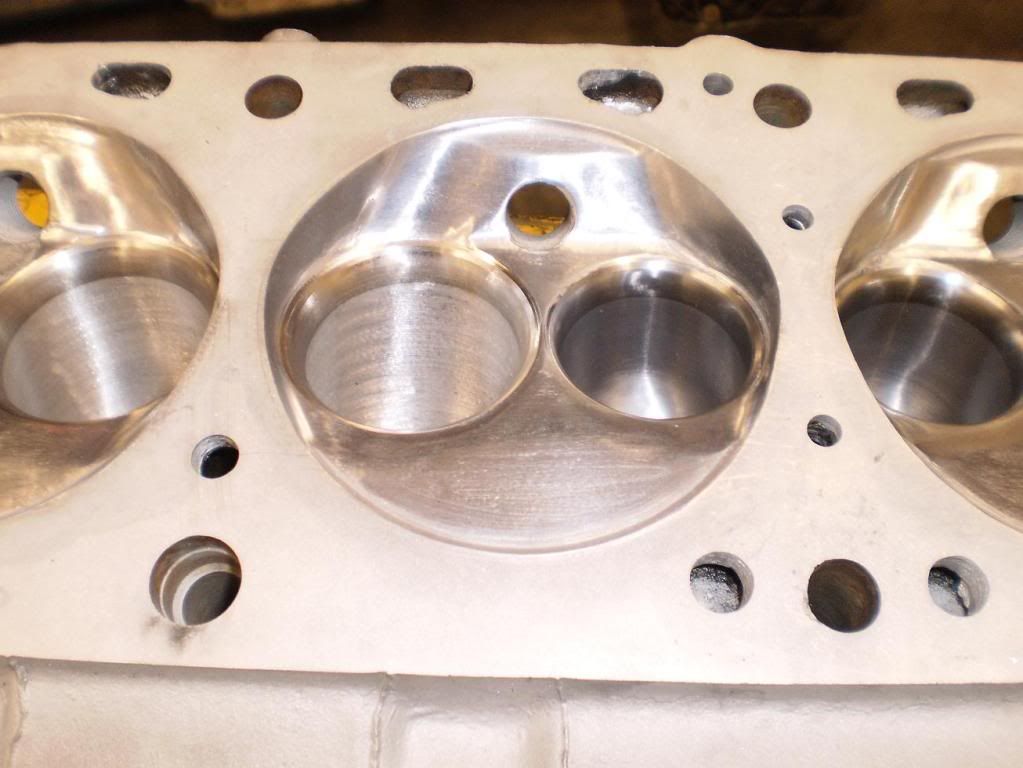

Those chambers were a prototype CNC porting method that has not been completed. That cylinder head has not been run on an engine yet; but maybe in a few years we'll see it finished up.

Thoughts? Obviously, if it's worth the better chamber shape to get a more consistent burn in this swirl-dominated system (very little tumble in the intake port on these) then I'll consider it. I am currently having issues with this engine wanting to go lean and putter in the 2500-3500RPM range; which is just when the boost is coming in...At 4000RPM, plug cuts reveal very evenly balanced chambers...but plug cuts at 2000, 2500, 3000, and 3500RPM show some cylinders very rich and some cylinders slightly rich; It's EFI and so I corrected the slightly rich chambers...but that still leaves the very rich chambers, well, rich and sooty.