Why an engine makes more power off a burr finish

Moderator: Team

-

groberts101

- Guru

- Posts: 1980

- Joined: Sat Mar 08, 2008 3:08 pm

- Location: Minneapolis

Re: Why an engine makes more power off a burr finish

I made a concerted effort to source some of the 3M material several years ago and the answer kept coming back : "No longer in production." I notice none of the references are dated later than 2010...Unkl Ian wrote:Interestingly, the 3m "riblets" appear to work in air, and water.

http://www.safl.umn.edu/featured-story/ ... iblet-film

http://nal-ir.nal.res.in/1340/

http://news.3m.com/press-release/compan ... -cup-match

http://www.nasa.gov/centers/langley/new ... blets.html

Felix, qui potuit rerum cognscere causas.

Happy is he who can discover the cause of things.

Happy is he who can discover the cause of things.

-

SchmidtMotorWorks

- Vendor

- Posts: 11003

- Joined: Mon Apr 11, 2005 2:30 am

- Location: CA

Re: Why an engine makes more power off a burr finish

There are cross sections but they are banded display, the shape I used is not a tube, it is an extruded section.David Redszus wrote:Hi Jon,

As we know, fluid flow in curved tubes (such as a port or inlet duct) will form twin counter rotating eddies.

Your flow graphics did not indicate such eddies. Could you show a slice perpendicular to air flow?

Now I wonder how longitudinal grooves will affect counter rotating eddies at higher Reynolds numbers.

Helping to Deliver the Promise of Flying Cars

Re: Why an engine makes more power off a burr finish

I did the same search for the Bonneville program with the same results. Does anyone have a source?MadBill wrote: I made a concerted effort to source some of the 3M material several years ago and the answer kept coming back : "No longer in production." I notice none of the references are dated later than 2010...

-

SchmidtMotorWorks

- Vendor

- Posts: 11003

- Joined: Mon Apr 11, 2005 2:30 am

- Location: CA

Re: Why an engine makes more power off a burr finish

It is avery easy mold to make, if you need a lot of it, you might break even, making your own mold.4sfed wrote:I did the same search for the Bonneville program with the same results. Does anyone have a source?MadBill wrote: I made a concerted effort to source some of the 3M material several years ago and the answer kept coming back : "No longer in production." I notice none of the references are dated later than 2010...

If the form can be extruded it is even less expensive.

Last edited by SchmidtMotorWorks on Thu Dec 18, 2014 4:21 pm, edited 1 time in total.

Helping to Deliver the Promise of Flying Cars

-

Kevin Johnson

- HotPass

- Posts: 9391

- Joined: Tue Nov 22, 2005 5:41 am

- Location:

Re: Why an engine makes more power off a burr finish

Perhaps Boeing: http://www.google.com/patents/CA2744753C?cl=en http://www.google.com/patents/WO2011037719A2?cl=en

Paint: http://link.springer.com/chapter/10.100 ... _23#page-1 http://www.ifam.fraunhofer.de/content/d ... r_ifam.pdf

Paint: http://link.springer.com/chapter/10.100 ... _23#page-1 http://www.ifam.fraunhofer.de/content/d ... r_ifam.pdf

MadBill wrote:I made a concerted effort to source some of the 3M material several years ago and the answer kept coming back : "No longer in production." I notice none of the references are dated later than 2010...Unkl Ian wrote:Interestingly, the 3m "riblets" appear to work in air, and water.

http://www.safl.umn.edu/featured-story/ ... iblet-film

http://nal-ir.nal.res.in/1340/

http://news.3m.com/press-release/compan ... -cup-match

http://www.nasa.gov/centers/langley/new ... blets.html

Driving Force Online: BREAKING NEWS—Ohio Governor Signs SEMA-Supported Vehicle Freedom Bill Into Law!

- af2

- Guru

- Posts: 7014

- Joined: Sun Jan 28, 2007 4:42 pm

- Location: Grass Valley, CA :Northern Foothills

Re: Why an engine makes more power off a burr finish

All this riblet stuff is making me hungry. Sad part is I can't taste anything still after 2 days.........

I really think back to porting 2 strokes. Except for heads you wanted a rough finish because the pockets were smaller than a polished/ smooth surface that would be hard to make straight and having valleys. Just a thought. It is hard to type my thoughts and experience with ports.

The exhaust is even more important with an expansion chamber to not have a polished port because the converging pulses don't like big jumps per say..

I really think back to porting 2 strokes. Except for heads you wanted a rough finish because the pockets were smaller than a polished/ smooth surface that would be hard to make straight and having valleys. Just a thought. It is hard to type my thoughts and experience with ports.

The exhaust is even more important with an expansion chamber to not have a polished port because the converging pulses don't like big jumps per say..

GURU is only a name.

Adam

Adam

Re: Why an engine makes more power off a burr finish

If you make a sizable/deep riblet parallel to the flow and direct all the fuel down the riblet you can probably get most of the fuel into the engine without any of it mixing with the air.  Enough said.

Enough said.

High Speed Combustion Pressure Tuning Equipment

TFX Engine Technology Inc.

tfx.engine@yahoo.com

www.tfxengine.com

TFX Engine Technology Inc.

tfx.engine@yahoo.com

www.tfxengine.com

-

Kevin Johnson

- HotPass

- Posts: 9391

- Joined: Tue Nov 22, 2005 5:41 am

- Location:

Re: Why an engine makes more power off a burr finish

Direct injection is still an improvement over that, though.

Driving Force Online: BREAKING NEWS—Ohio Governor Signs SEMA-Supported Vehicle Freedom Bill Into Law!

-

groberts101

- Guru

- Posts: 1980

- Joined: Sat Mar 08, 2008 3:08 pm

- Location: Minneapolis

Re: Why an engine makes more power off a burr finish

I got sucked into reading research papers too. lol

This one also goes into detail about the decreasing efficiency and subsequent drag if they're not implemented properly.

http://torroja.dmt.upm.es/~ricardo/pres ... Tpaper.pdf

I find it highly doubtful, nearly impossible, that we would ever be able to design, not to even mention realistically utilize, the "perfect dimple" in this entire environment. What would help in one area would likely hurt in another due to the constantly changing environments within a port. Which would inevitably mandate the use of several varying surface design, size,and location.

However, I do firmly believe that even if a port is potentially overdone with this surface treatment(too deep over too large an area and in the wrong locations).. in some ports the benefits can and do still outweigh any potential downsides when compared to a smooth port.

This one also goes into detail about the decreasing efficiency and subsequent drag if they're not implemented properly.

http://torroja.dmt.upm.es/~ricardo/pres ... Tpaper.pdf

I think there's still plenty to learn here. In my mind, the speed and directional change associated with the mass being examined plays a huge roll in what actually works best.. or even at all in any particular environment. This is much tougher to nail down than many of these other examples because of the ultra high speed ebbing and pulsating nature of suspended liquid fuel within an induction system.As the Reynolds number of the riblets increases, the predictions of the viscous theory, and in particular the

linear dependence of the drag reduction with s

+, break down. This is the regime that ultimately limits the

practical performance of riblets, and understanding it is therefore important. In particular, if it could be shown

that the Reynolds number of breakdown is somehow related to the geometry of the riblet, it might be possible

to devise surfaces with critical Reynolds numbers higher than the present ones, and consequently with higher

peak performances. We will see in Section 3.2 that there is some evidence for this possibility, but the range of

optimum spacings is narrow, and the reason for their variation is, in any case, not understood.

The theories for why the effect of riblets deteriorates beyond s

+ ≈ 10 fall into two broad groups. One

is that their effect on the crossflow somehow loses effectiveness once the flow moves away from the Stokes

regime. Reference [14], already mentioned in the introduction, is in that class. They propose that, once the

crossflow over the riblets starts separating and shedding small-scale vortices, the extra dissipation appears in

the flow as drag. We have also mentioned contradictory evidence, both from unsteady spanwise oscillations

of the wall, which decrease drag even if they presumably introduce extra vorticity [21], and from numerical

experiments that increase drag by inhibiting the formation of secondary vortices [17, 20]. The message of those

experiments could be that introducing small-scale streamwise vorticity at the wall decreases drag by damping

the larger streamwise vortices of the buffer layer, and therefore that inertial crossflow effects could be beneficial,

rather than detrimental, for drag reduction. The other group of theories assumes that the observed optimum

wavelength, s

+ ≈ 10 − 20, is related to the scale of the turbulent structures in the wall region. In that group

we could mention the observations in [29, 23, 6] that the degradation of the drag reduction coincides with the

lodging of the vortices within the riblet grooves. A possibility that did not seem to have been considered in

the literature is that the concept of protrusion height could be extended beyond the strictly viscous regime,

and that the observed deviations from linearity are due to nonlinearities within, but not necessarily above, the

riblets.

I find it highly doubtful, nearly impossible, that we would ever be able to design, not to even mention realistically utilize, the "perfect dimple" in this entire environment. What would help in one area would likely hurt in another due to the constantly changing environments within a port. Which would inevitably mandate the use of several varying surface design, size,and location.

However, I do firmly believe that even if a port is potentially overdone with this surface treatment(too deep over too large an area and in the wrong locations).. in some ports the benefits can and do still outweigh any potential downsides when compared to a smooth port.

Last edited by groberts101 on Thu Dec 18, 2014 5:41 pm, edited 4 times in total.

-

Kevin Johnson

- HotPass

- Posts: 9391

- Joined: Tue Nov 22, 2005 5:41 am

- Location:

Re: Why an engine makes more power off a burr finish

Nice paper with meta-analysis. Also points out how important it is to publish scientific results in English nowadays for human researchers.

Aside: while investigating cryo-treatments I ran across results published in Russian of work done in the 1930s. (provided by the British) Previously had only heard of Junkers -- saw follow up at MIT. In the USF library there are complete sections of Russian technical journals. When AI advances just a wee bit more ... watch out.

Aside: while investigating cryo-treatments I ran across results published in Russian of work done in the 1930s. (provided by the British) Previously had only heard of Junkers -- saw follow up at MIT. In the USF library there are complete sections of Russian technical journals. When AI advances just a wee bit more ... watch out.

Driving Force Online: BREAKING NEWS—Ohio Governor Signs SEMA-Supported Vehicle Freedom Bill Into Law!

Re: Why an engine makes more power off a burr finish

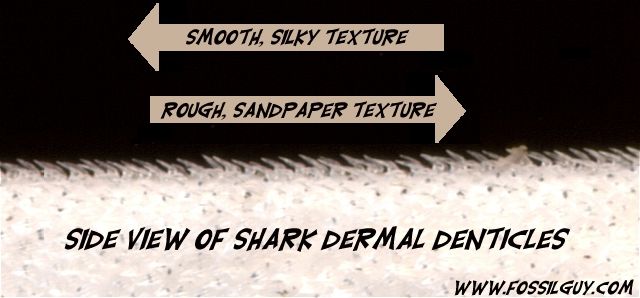

Along those lines, nothing to do with ports, but are those denticles found on a shark's fins as well? I could see them acting in the fashion of a 'hydraulic diode', 'grabbing' the water during the thrust portion of the fin/tail's movement but slipping more smoothly through it on the return stroke...

Felix, qui potuit rerum cognscere causas.

Happy is he who can discover the cause of things.

Happy is he who can discover the cause of things.

-

SchmidtMotorWorks

- Vendor

- Posts: 11003

- Joined: Mon Apr 11, 2005 2:30 am

- Location: CA

Re: Why an engine makes more power off a burr finish

I ran a test of extruded dimples on a very fine mesh.

The first 5 dimples on the left are meshed at 0.003" after that they gradually progress up to 0.030"

The rule of thumb I had been using for mesh size on larger models turns out to be reasonable, for this work, that is:

The mesh is close enough to provide useful understanding of a concept when it is at least as close as your manufacturing tolerance for flow determining dimensions. This an 80/20 case where you get 80% of the desired information for 20% of the effort, the next 20% would require the other 80% of work (or at least waiting for your computer). Since the difference doesn't change understanding significantly, I don't think I will do the fine mesh unless I become interested in trying some designed texture.

I snapped some interesting images of the fine mesh run, I'll post now.

Small mesh velocity:

The first 5 dimples on the left are meshed at 0.003" after that they gradually progress up to 0.030"

The rule of thumb I had been using for mesh size on larger models turns out to be reasonable, for this work, that is:

The mesh is close enough to provide useful understanding of a concept when it is at least as close as your manufacturing tolerance for flow determining dimensions. This an 80/20 case where you get 80% of the desired information for 20% of the effort, the next 20% would require the other 80% of work (or at least waiting for your computer). Since the difference doesn't change understanding significantly, I don't think I will do the fine mesh unless I become interested in trying some designed texture.

I snapped some interesting images of the fine mesh run, I'll post now.

Small mesh velocity:

You do not have the required permissions to view the files attached to this post.

Helping to Deliver the Promise of Flying Cars

-

SchmidtMotorWorks

- Vendor

- Posts: 11003

- Joined: Mon Apr 11, 2005 2:30 am

- Location: CA

Re: Why an engine makes more power off a burr finish

Small mesh single dimple, there is an eddy but it is moving slowly.

You do not have the required permissions to view the files attached to this post.

Last edited by SchmidtMotorWorks on Thu Dec 18, 2014 8:50 pm, edited 1 time in total.

Helping to Deliver the Promise of Flying Cars