(stock cam) .389 lift 193 duration at .050 intake and exhaust on a 110 lobe sep

(replacement cam) .407 lift 198 duration intake, .415 204 duration exhaust on a 109 lobe separation.

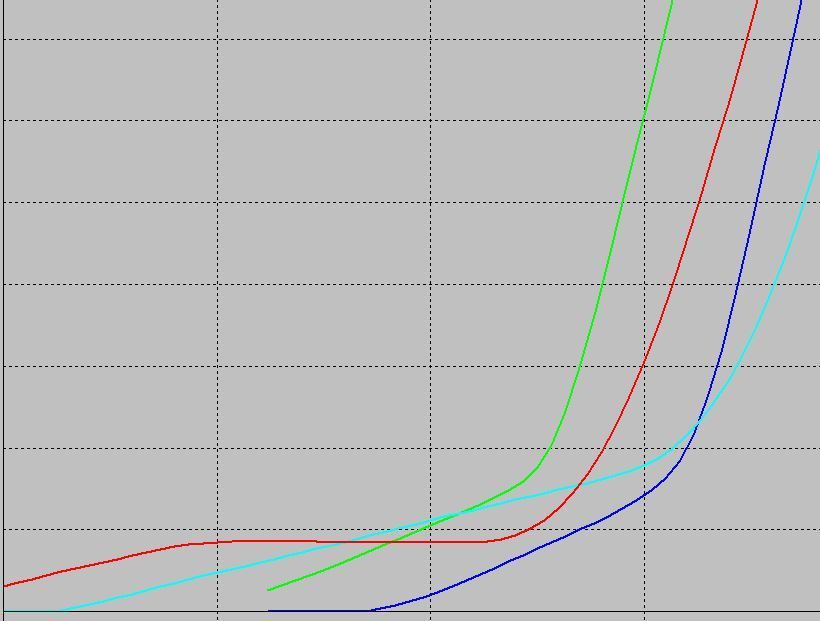

What I found interesting are how the ramps are designed on all the lobes on both the opening and closing sides..

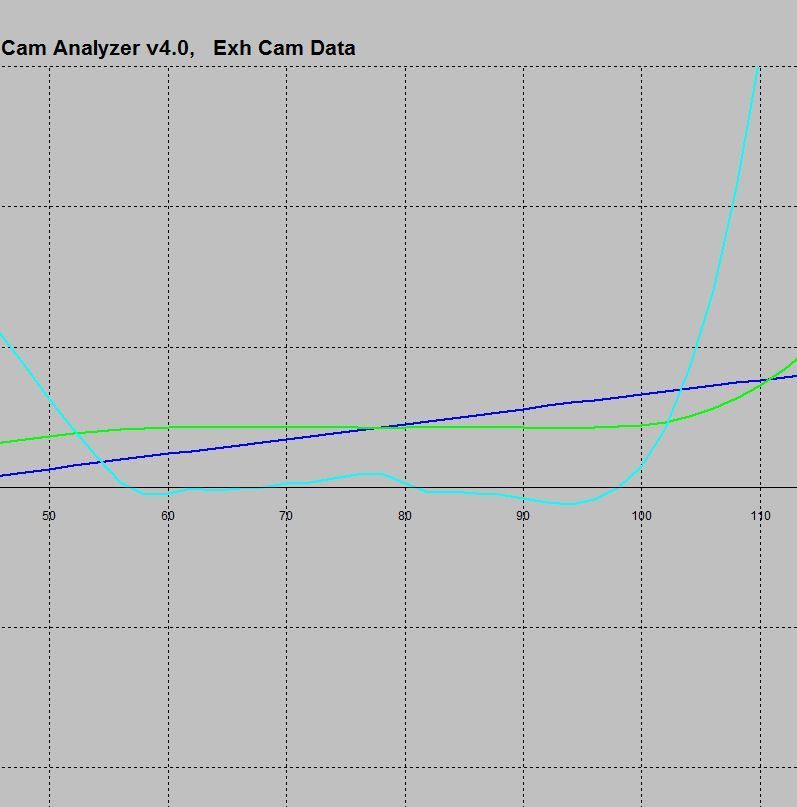

Here I zoomed way in on the opening ramp of the exhaust lobe on the replacement camshaft. See how there is a VERY long constant velocity section of the ramp which goes from about 60 degrees in the graph all the way over to about 98 degrees during which the velocity in inches per degree only changes from .000426 to .000432. Lift over that distance changes from .00479 to .01285. So given the engine's 1.5 ratio rocker it seems like the lash could be set anywhere from about .007 to .020 with no real change in contact velocity. In other words the cam would run as quietly at .020 as it would at .007... Did OEM manufacturers design cams this way so that it could run a very long time and even be way out of adjustment yet the contact velocity would still remain very low?

It seems like this idea wouldn't be terribly useful in a performance application where it is assumed that the lash will be checked more often and kept within a reasonable range of adjustment. What are the effects of this sort of design on performance?