Page 1 of 6

Is Port Energy validation just around the corner?????

Posted: Sat Sep 23, 2017 11:36 am

by David Vizard

Had a very interesting email and photos from an engineer that has designed an intake port that can vary it's area over a significant length.

I am not going to show it here and I have advised him not to show it around as I feel it is patentable. I am really excited about this because the variable area means that port energy can be optimized at every rpm point in the rev range.

So will I be proved right on this subject or will all those who hold a contradictory position prove to be right?

Now is the time to start running a book. Who is going to take charge of the bets???

DV

Re: Is Port Energy validation just around the corner?????

Posted: Sat Sep 23, 2017 11:48 am

by psychomotors

Very interesting.

Re: Is Port Energy validation just around the corner?????

Posted: Sat Sep 23, 2017 11:51 am

by user-17438

Isn't there already a patent for that? I know there are on variable cross section intake manifolds and a lot of 4 valve engines have different sizes..

Re: Is Port Energy validation just around the corner?????

Posted: Sat Sep 23, 2017 11:54 am

by David Vizard

MTENGINES wrote:Isn't there already a patent for that? I know there are on variable cross section intake manifolds and a lot of 4 valve engines have different sizes..

The concept cannot be patented the the means of doing it can.

DV

Re: Is Port Energy validation just around the corner?????

Posted: Sat Sep 23, 2017 12:04 pm

by Carnut1

During hurricane Irma I was witness to what 90+ mph winds can do, that only calcs to 132 ft/sec. Since energy goes up as the square of velocity I know which way I am betting! Thanks, Charlie

Re: Is Port Energy validation just around the corner?????

Posted: Sat Sep 23, 2017 12:34 pm

by Carnut1

0914171110.jpg

Destructive force of 132 ft/sec air.

Posted: Sat Sep 23, 2017 3:22 pm

by dwilliams

Back in the '70s someone was touting a variable-area port. Rectangular port with a hinged floor, moved up and down to vary the area. It was supposed to keep velocity up to boost torque on downsized smog motors.

BMW(?) was showing around something similar in the '90s, back when "variable intake geometry" was the new hotness.

The obvious extension of the idea would be to use your variable-area port as a throttle, but sealing would be interesting. Engines need very little air at idle, so even tiny amounts of leakage on a per-cylinder basis would be a problem.

Re: Is Port Energy validation just around the corner?????

Posted: Sat Sep 23, 2017 4:23 pm

by Brian P

There have been a number of means of getting a 4-valve-per-cylinder engine to only use one intake port per cylinder over the years.

Honda VFR800 engines with "VTEC" completely disable one intake valve and one exhaust valve per cylinder below a certain RPM using what amounts to collapsible lifters. This showed up in production around 15 years ago.

Lots of engines with 2 intake valves per cylinder have inlet ports that are fully separated within the cylinder head and use some sort of secondary throttle to block off one intake runner per cylinder at lower revs (generally under ECU control). This is all downstream of the main throttle, so it doesn't have to seal perfectly. This, again, has been around for decades.

Varying the actual port area, as opposed to a binary switch-off of half of the intake area via effectively switching between 2-valve and 4-valve operation ... is more difficult but could be interesting.

I would already consider the concept of "port energy" to be validated, it's just hard to make it happen other than by binary switch-off of half of the effective area.

Re: Is Port Energy validation just around the corner?????

Posted: Sat Sep 23, 2017 4:30 pm

by ptuomov

Brian P wrote:There have been a number of means of getting a 4-valve-per-cylinder engine to only use one intake port per cylinder over the years.

Honda VFR800 engines with "VTEC" completely disable one intake valve and one exhaust valve per cylinder below a certain RPM using what amounts to collapsible lifters. This showed up in production around 15 years ago.

Lots of engines with 2 intake valves per cylinder have inlet ports that are fully separated within the cylinder head and use some sort of secondary throttle to block off one intake runner per cylinder at lower revs (generally under ECU control). This is all downstream of the main throttle, so it doesn't have to seal perfectly. This, again, has been around for decades.

Varying the actual port area, as opposed to a binary switch-off of half of the intake area via effectively switching between 2-valve and 4-valve operation ... is more difficult but could be interesting.

I would already consider the concept of "port energy" to be validated, it's just hard to make it happen other than by binary switch-off of half of the effective area.

The tumble flaps that can be controlled would not only change the port area but also induce more tumble motion at low mass air flow rates. I'm not sure if those have been implemented in production engines.

Re: Is Port Energy validation just around the corner?????

Posted: Sat Sep 23, 2017 6:01 pm

by digger

A rubber diaphragm as the port walls that can be expanded. It would form a natural Venturi of sorts to

Re: Is Port Energy validation just around the corner?????

Posted: Sat Sep 23, 2017 6:28 pm

by David Vizard

digger wrote:A rubber diaphragm as the port walls that can be expanded. It would form a natural Venturi of sorts to

it would also come apart quickly due to the big and rapid changes in pressure.

DV

Re: Is Port Energy validation just around the corner?????

Posted: Sat Sep 23, 2017 8:02 pm

by BOOT

David Vizard wrote:an intake port that can vary it's area over a significant length.DV

Sounds a lot better than a variable choke point that some use. It would have to be simplistic to avoid ingesting small pieces when they come loose and internal to also avoid sealing issues. I wouldn't want to use hydraulic pressure either really to avoid leaks and contaminate the fuel. Maybe something effected by the velocity like weighted rollers or flaps of some sort. Something tunable effected by the velocity change but not by reversion, I wouldn't want it to flip-flop and wear(debris).

My bet is something inflatable under a layer that is mostly isolated or even just a layer/wall that is lifted at several points with actuators, that's prob how I'd attempt to do it if I had the resources.

Re: Is Port Energy validation just around the corner?????

Posted: Sat Sep 23, 2017 8:03 pm

by hoffman900

Port energy (or energy density) is essentially expressed as pressure in a fluid (which air is).

The higher the velocity of a fluid, the lower the pressure.

The name of the game is pressure recovery. The more pressure you can recover at the valve, the greater the delta P between the cylinder pressure (at its lowest) and the port pressure. It also raises the pressure ceiling at which the valve would need to close, thus extending your filling time.

As Harold Brookshire once very plainly put on here, an engine works off of pressure differentials (differential equations).

If you want to see a strict pressure recovery design exercise at its best in the context of engines, look at inlet restrictor design in the FSAE world. This assumes a more linear state of pressure drop, which a port is absolutely not.

Seeing how you can vary the min. choke area (which this patent may do), you still need to optimize the shape of the recovery section of the nozzle, otherwise, it's a exercise in who can create the most potential energy, but may do little in creating more utilized energy.

Furthermore, pressure in an intake port follows that of a sinusoidal curve, the timing of such, is in fact, manipulable in real time, with many examples. Some designs do better at utilizing this and you need to look at this from where the intake tract starts to the valve seat, through the combustion chamber.

Re: Is Port Energy validation just around the corner?????

Posted: Sat Sep 23, 2017 8:55 pm

by swampbuggy

Bob, could you explain exactly what you mean by SINUSOIDAL CURVE--------and does this have anything in common with Darin Morgans statement --an induction system is virtually untunable until you get to at least 6500 RPM's .

Re: Is Port Energy validation just around the corner?????

Posted: Sat Sep 23, 2017 9:11 pm

by hoffman900

swampbuggy wrote:Bob, could you explain exactly what you mean by SINUSOIDAL CURVE--------and does this have anything in common with Darin Morgans statement --an induction system is virtually untunable until you get to at least 6500 RPM's .

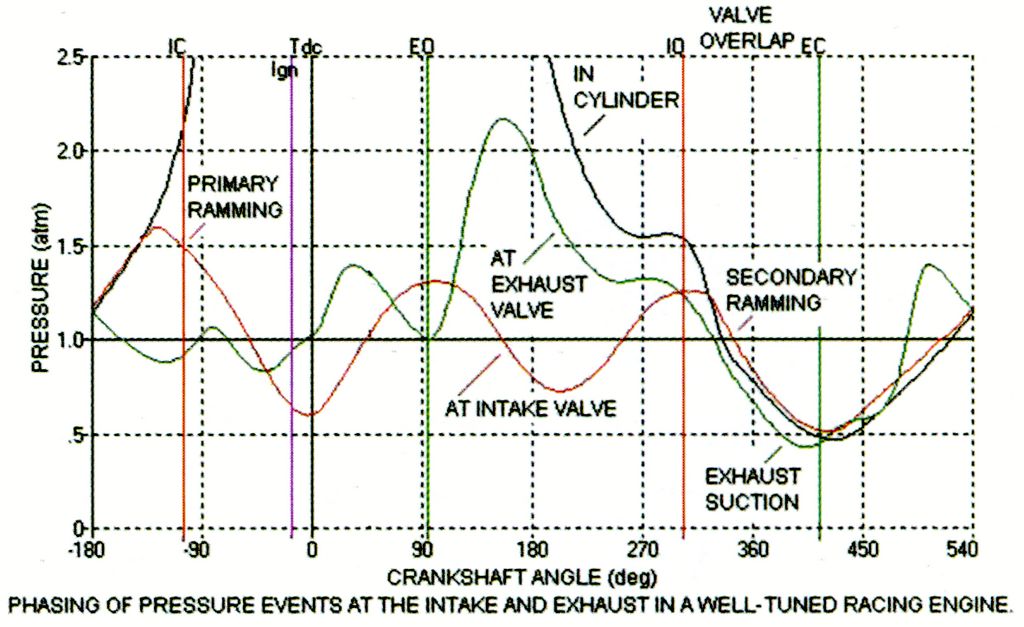

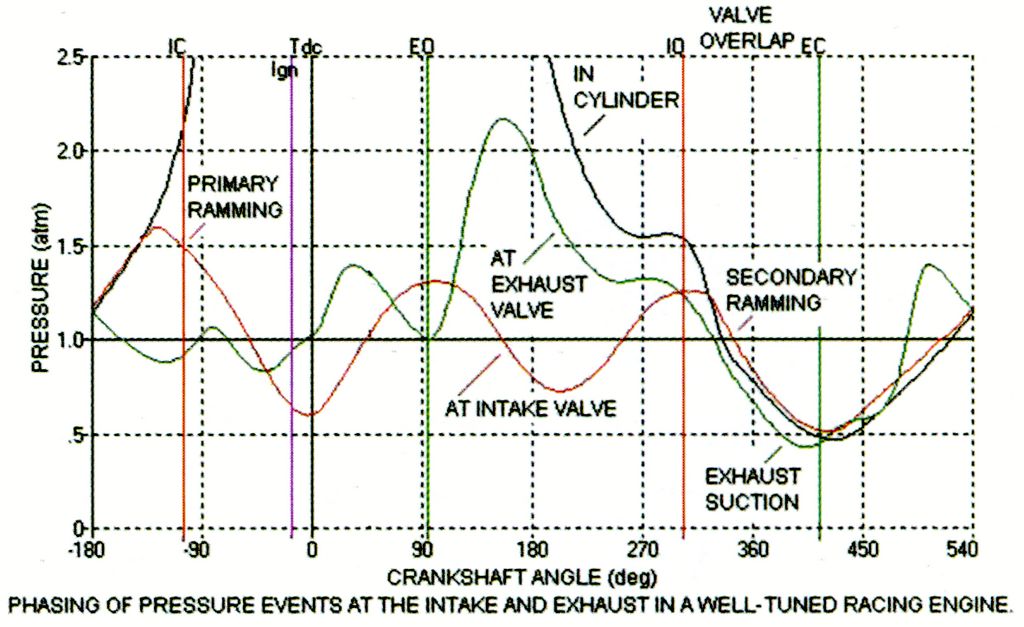

I'm not sure what this is measured from (from an old Speedtalk thread), but this is a pressure graph from an engine, showing intake and exhaust port pressures vs cylinder pressure on the Y axis, and crankshaft degrees on the X-axis.

The red is the intake port pressure. The pressure bounces in a sine wave (sinusoidal) pattern until intake valve open. Then the port pressure falls because velocity is high (delta P is high). The port velocity decreases at at ever increasing amount so pressure increases (but stays above cylinder pressure, so thus flow is moving in the positive direction). Just about when they meet the valve closes.

I would have to see Darin's comment before I comment.

Read this:

http://citeseerx.ist.psu.edu/viewdoc/do ... 1&type=pdf.