Got photos of what you ended up doing?bentvalves wrote: ↑Wed Mar 28, 2018 6:15 pm NEGATIVE. Once the head leaves my door, these guys are usually pretty tight lipped about whats going on.

dyno graphs posted online and 1/4 mile timeslips lead me to believe I was headed in the right direction.

de-shroud in or ex

Moderator: Team

Re: de-shroud in or ex

Paradigms often shift without the clutch -- https://www.youtube.com/watch?v=cxn-LxwsrnU

https://www.instagram.com/ptuomov/

Put Search Keywords Here

https://www.instagram.com/ptuomov/

Put Search Keywords Here

Re: de-shroud in or ex

Since you are talking 4 valve combustion chamber shapes and shrouding you should talk to the people at Endyne,. They have done a lot of research and development on this subject including turbocharged applications.

www.theoldone.com

www.theoldone.com

The Older I Get, The Dumber I Get

Re: de-shroud in or ex

I'd just be curious in seeing what the original poster did and understand his logic. More data points is better, in my opinion.Newold1 wrote: ↑Wed Mar 28, 2018 7:24 pm Since you are talking 4 valve combustion chamber shapes and shrouding you should talk to the people at Endyne,. They have done a lot of research and development on this subject including turbocharged applications.

www.theoldone.com

Paradigms often shift without the clutch -- https://www.youtube.com/watch?v=cxn-LxwsrnU

https://www.instagram.com/ptuomov/

Put Search Keywords Here

https://www.instagram.com/ptuomov/

Put Search Keywords Here

Re: de-shroud in or ex

The engine that I’m playing with doesn’t appear to benefit hugely from deshrouding the valves, but there’s a little bit that could be done both on the head combustion chamber did and on the piston side. With bigger valves you’d of course need to do more:

You do not have the required permissions to view the files attached to this post.

Paradigms often shift without the clutch -- https://www.youtube.com/watch?v=cxn-LxwsrnU

https://www.instagram.com/ptuomov/

Put Search Keywords Here

https://www.instagram.com/ptuomov/

Put Search Keywords Here

-

Erland Cox

- Guru

- Posts: 4162

- Joined: Sun Jan 29, 2006 9:46 pm

- Location: Lund in Sweden

- Contact:

Re: de-shroud in or ex

ptuomov wrote: ↑Mon Dec 18, 2017 5:22 pmAlso interested in the answer.bentvalves wrote: ↑Mon Dec 18, 2017 5:13 pm4 valves per cylinder, modern pentroof chamber.

if you had to pick a side to de-shroud which one takes priority in a turbocharged engine and why?

in my minds eye the exhaust valve side needs the help as the intake side is already being helped by the turbo....

but I'm still green

My logic would say that if the intake manifold pressure and exhaust manifold pressure are about equal, doing whatever one does for a normally aspirated version of the engine would be the way to go.

I agree.

Erland

-

Erland Cox

- Guru

- Posts: 4162

- Joined: Sun Jan 29, 2006 9:46 pm

- Location: Lund in Sweden

- Contact:

Re: de-shroud in or ex

On this head I have just continued the chamber into the squish pads to soften the chamber.

Erland

Erland

-

Trial n Error

- New Member

- Posts: 17

- Joined: Sat Apr 30, 2011 2:13 am

- Location:

Re: de-shroud in or ex

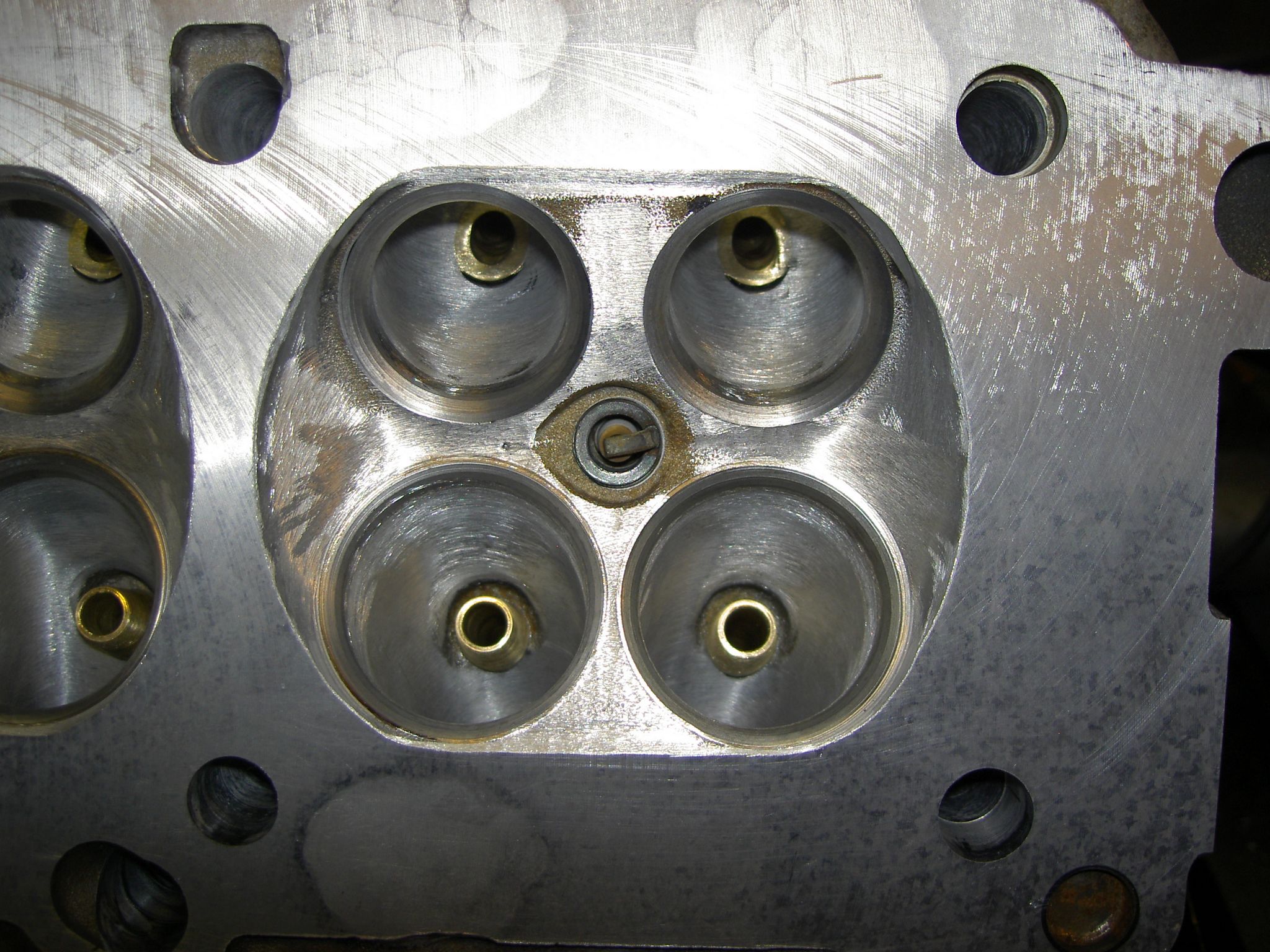

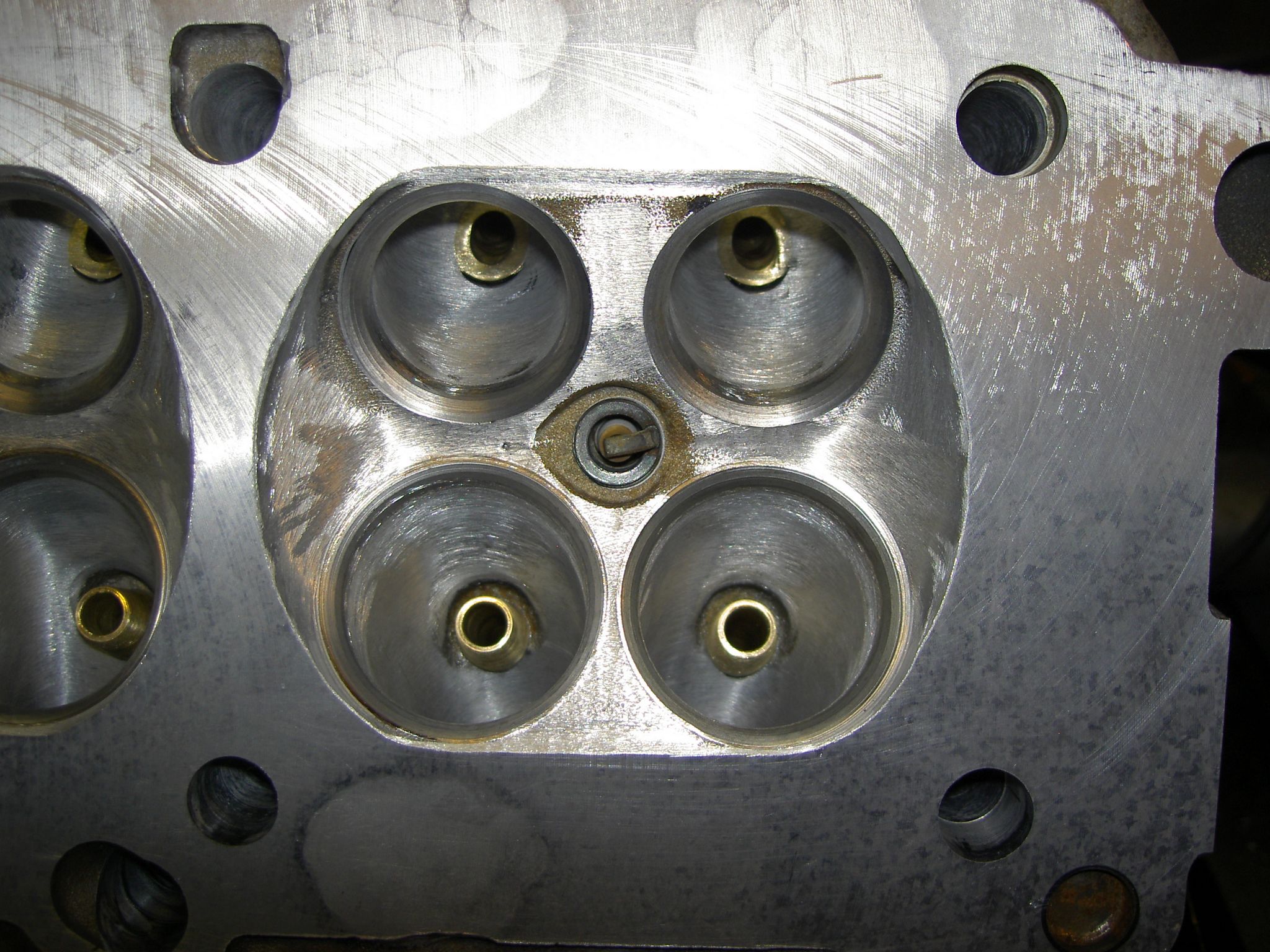

This is a Toyota 7MGTE I played with a few years ago. (Im still after a dyno on it!)

I chased as much flow as possible at all points in the lift. I managed a healthy average flow increase of 7%, with 15CFM at 7mm. (7.5mm total cam lift) for the intake side. Exhaust I bumped up low to mid lift by some 15CFM in places to flattened out to about the same as stock at peak lift. I would guess it could do with a bigger exhaust valve or throat. The intake could do with the same as the ports are very large. I did shrink the ports by 20% and achieved the same flow numbers. But the material I used did not stick as well as I hoped. I would say more my fault than what I used.

Where the chamber is shiny between the intake/exhaust valves was a "peak" to increase compression. By removing this it lost 0.3 points in compression, but helped assist in the increase in flow.

I left the sides as they were in the hope to direct fuel into the center of the bore, rather than over a hot exhaust valve. Or worse, out them completely.

As this head sits atop a short-block with standard everything. The owner is very happy as he upgraded from a N/A version.

What is noticeable is its very easy to drive and has a N/A multi-valve power band to it. These motors were not exceptional in the higher PRM band due to the motors long stroke which makes this one very different. It only runs 10psi using a standard 80s ECU, yet this motor has no issues exceeding 5000RPM with a surge of urgency to "keep going". Of course a dyno plot would completely justify the unreliable "butt dyno" experience but its all I have.

NOTE - this photo was taken after completing the hand work. A 3 angle seat cut, valve re-face and head re-face were all preformed before it was put back on the motor.

Re: de-shroud in or ex

“Where the chamber is shiny between the intake/exhaust valves was a "peak" to increase compression. By removing this it lost 0.3 points in compression, but helped assist in the increase in flow.”

I think (but don’t know) that those ridges or jumps between intake and exhaust valves are there to prevent fresh charge from the intake from flowing directly into the exhaust. I think that it’s only a big deal in terms of emissions.

Is this a turbo or supercharged engine?

I think Toyota has changed their head design philosophy a little from way back when. I think now they want the intake port angle to be normal (90-degree angle) relative to the exhaust valve faces:

I think (but don’t know) that those ridges or jumps between intake and exhaust valves are there to prevent fresh charge from the intake from flowing directly into the exhaust. I think that it’s only a big deal in terms of emissions.

Is this a turbo or supercharged engine?

I think Toyota has changed their head design philosophy a little from way back when. I think now they want the intake port angle to be normal (90-degree angle) relative to the exhaust valve faces:

You do not have the required permissions to view the files attached to this post.

Paradigms often shift without the clutch -- https://www.youtube.com/watch?v=cxn-LxwsrnU

https://www.instagram.com/ptuomov/

Put Search Keywords Here

https://www.instagram.com/ptuomov/

Put Search Keywords Here

-

Trial n Error

- New Member

- Posts: 17

- Joined: Sat Apr 30, 2011 2:13 am

- Location:

Re: de-shroud in or ex

Sorry, not trying to hi-jack the thread.

On the 7M head, from what I can see is based on a 4age 16V big port design. It was a trick of Japan to extend existing 4 cylinder design into 6 cylinder due to cost. Nissan did it with a CA 4 cyl series and made the RB 6 cyl series of motors.

The shiny sections I referred to is between the valves for de-shrouding. The sections that are directly above and below the spark-plug were shaped following the standard casting. All I did was push the chamber wall away from the sides of the intake valve. This helped in the mid to high lift zones.

As this is fitted with a turbo charger, I did my best to try and get the incoming air to not go out the exhaust valves. What cannot be seen is a gentle hump between the intake and exhaust, right along the line of the spark plug. I left this too so the air would not shoot straight from the intake seat to the exhaust seat.

I really need to convince the owner to get it on a dyno so a greater understanding of what I have done verse what has been achieved.

On the 7M head, from what I can see is based on a 4age 16V big port design. It was a trick of Japan to extend existing 4 cylinder design into 6 cylinder due to cost. Nissan did it with a CA 4 cyl series and made the RB 6 cyl series of motors.

The shiny sections I referred to is between the valves for de-shrouding. The sections that are directly above and below the spark-plug were shaped following the standard casting. All I did was push the chamber wall away from the sides of the intake valve. This helped in the mid to high lift zones.

As this is fitted with a turbo charger, I did my best to try and get the incoming air to not go out the exhaust valves. What cannot be seen is a gentle hump between the intake and exhaust, right along the line of the spark plug. I left this too so the air would not shoot straight from the intake seat to the exhaust seat.

I really need to convince the owner to get it on a dyno so a greater understanding of what I have done verse what has been achieved.