In my case 'the perfect geometry' gave way to packaging constraints: Huge included valve angle, skinny pushrod tube to house my fat tapered pushrods and a bunch of other factors that led to a rather compromised geometry on the valve side.

A point that became very obvious early in the design process, and has been mentioned here a couple times, is the importance of the pushrod side geometry. This is critical. Small changes are amplified through the RR to become big upsets at the valve. 90 deg at mid lift is the most faithful means of transmitting cam information while minimising lateral pushrod movement. The latter point being particularly important in my case.

So I concentrated on getting the pushrod side right then dealt with the consequences on the other side. What I eventually (and I mean eventually!) ended up with is what the OP mentioned as 'low pivot'. But really low. In my case the 90 deg point isn't around Jesel's 2/3's lift range, but just a few cam degrees before max lift. However, this could prove advantageous when you consider maximum piston speed or piston demand.

An observation before I go on: It's an easy habit to think of rocker ratio in terms of lift and forget the huge influence on duration at the valve - arguably more important because, as I see it, it is the stretched duration that contributes most to the area under the curve. The 90 degree point dictates the position of maximum stretch so wouldn't it make sense to put that stretch at the point of maximum piston speed i.e. max piston demand? Is that not Jesel's thinking? (I know there is inertial delay thrown into the equation). A fun thought experiement if nothing else.

The V8 guys among you (i.e. all of you

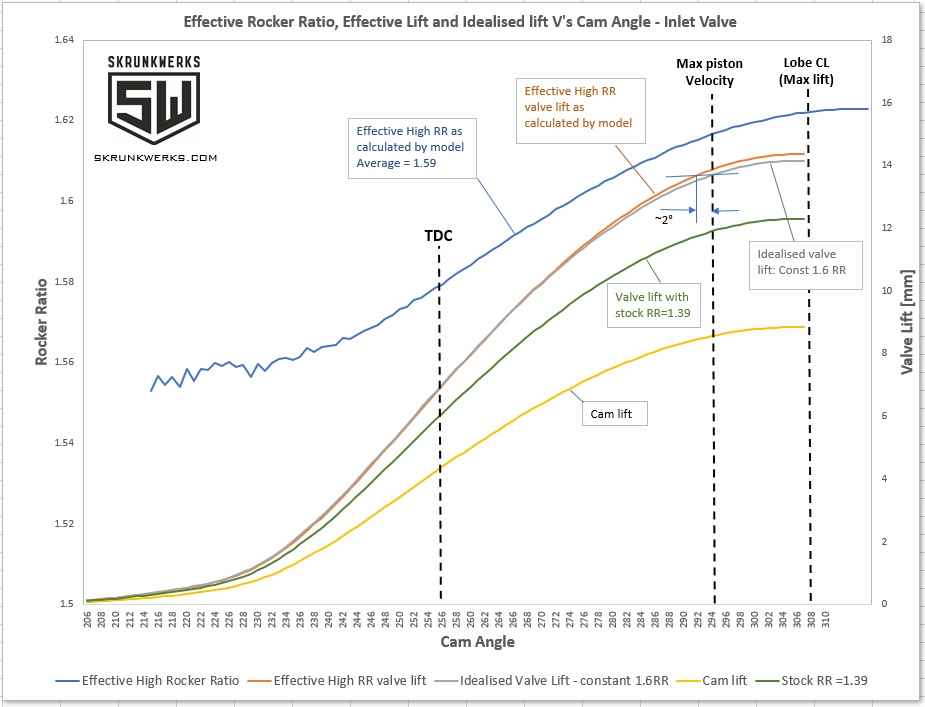

The graph below shows the actual effective RR as the rocker rotates through it's arc. The RR varies from ~1.56 at open through to 1.62 at peak lift. As an exersise I compared this with an idealised curve with constant RR of 1.6 (which was my target RR). As expected, not much in the flanks though you can see the curves cross a few degrees before TDC. The action occures closer to max lift where the 90 deg point is. At max piston speed an increase in duration of approx 2 deg (half the cam) is apparent. That's 8 deg at the crank.

Whether any of this makes a zack of difference is the question. A fun academic exersise with results lost in dyno noise between pulls? Particularly in my case where gains are in the upper portion of the lift profile - not as much bang for buck as in the 'body' of the profile. Haven't tested them yet - we'll see.